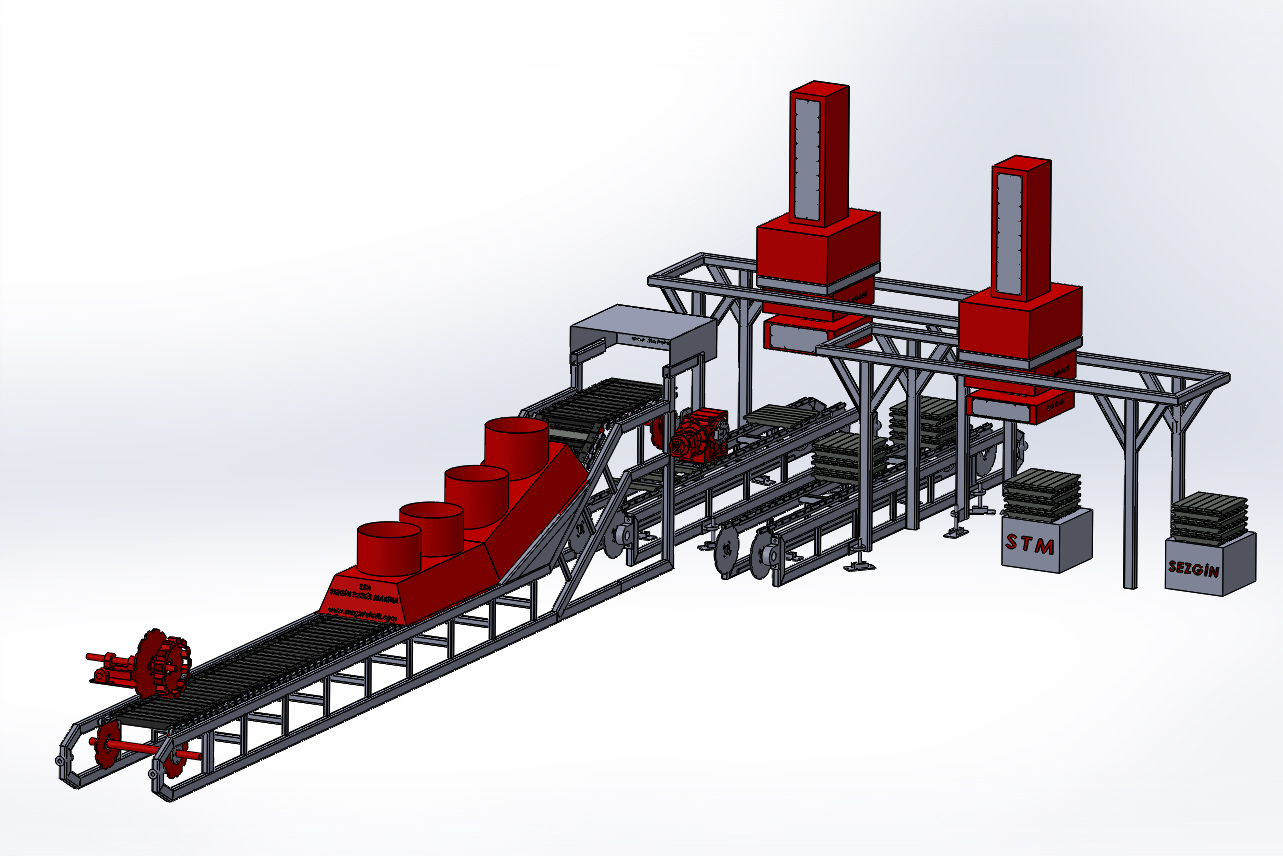

Revolutionize your end-of-line production with the STM Ingot Stacking Robot. This high-speed robotic solution eliminates the most grueling manual task in the foundry—lifting and stacking heavy ingots. Engineered for precision and safety, it creates perfectly aligned, stable bundles ready for transport, ensuring 24/7 consistency without fatigue.

-

Precision Grip Technology: Secure handling for various ingot shapes and sizes.

-

High-Speed Throughput: Capable of matching the output of your fastest casting conveyors.

-

Heavy Payload Capacity: Designed for lead, aluminum, and zinc ingot bundles.

| Feature | Specification |

| Payload Capacity | Up to 50kg per cycle (Customizable) |

| Stacking Height | Up to 1500mm |

| Cycle Time | < 6 seconds per ingot |

| Drive System | AC Servo Motors with Precision Gearboxes |

| Control Interface | 10″ Color Touchscreen PLC |

| Safety Rating | ISO 10218-1 Compliant |

Why Choose the STM Stacking Robot?

-

📈 Maximize ROI: One robot replaces multiple manual labor shifts, paying for itself within the first year of operation.

-

🏥 Workplace Safety: Eliminate long-term musculoskeletal injuries caused by repetitive heavy lifting.

-

📦 Space Optimization: Create tighter, more uniform stacks that save valuable warehouse and container space.