Maximize Efficiency. Minimize Waste.

In high-volume casting, precision is measured in degrees and seconds. STM Sezgin Teknik provides a comprehensive range of furnace attachments and casting accessories engineered to preserve heat, reduce energy waste, and ensure the highest metallurgical purity. From the moment you charge your furnace to the final pour, our equipment is built to optimize your ROI.

1. High-Performance Furnace Attachments

-

Furnace Charging Attachment: * Load Faster, Save Heat.

-

Benefit: Optimized for rapid material entry, reducing the time doors stay open. This prevents massive heat loss and lowers the energy required to bring the melt back to target temperature.

-

-

Furnace Skimming & Cleaning Attachments: * Purity Without the Pain.

-

Benefit: Specifically designed for effortless dross removal. Reach every corner of the furnace with ergonomic precision, ensuring a clean melt without damaging the delicate refractory lining.

-

2. Advanced Casting & Molten Metal Transfer

-

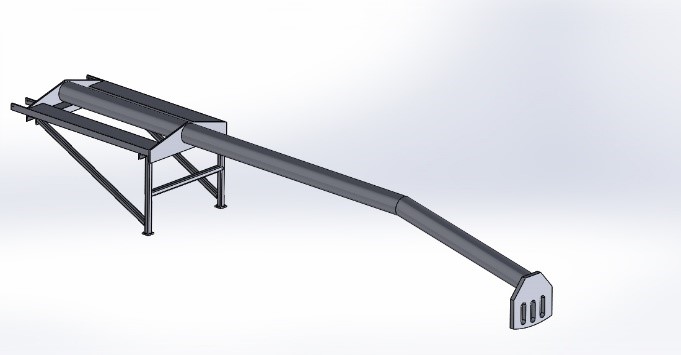

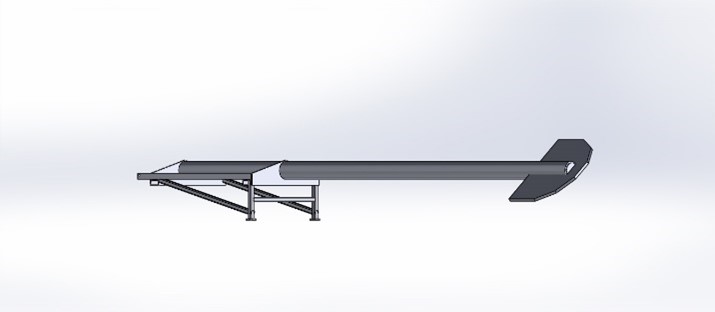

Insulated “Yolluk” (Launders & Runners): * Stable Temperatures, Flawless Pours.

-

The Magic: Superior thermal insulation ensures molten metal maintains a stable temperature from furnace to mold.

-

Benefit: Because the metal stays fluid and hot, you can use fine-mesh filters without them breaking or “freezing,” resulting in the cleanest possible ingots.

-

-

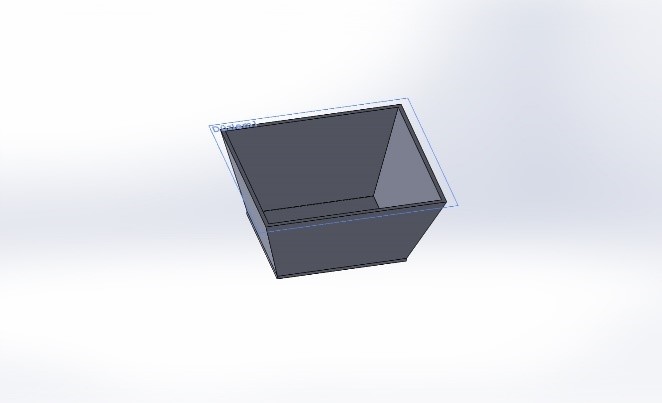

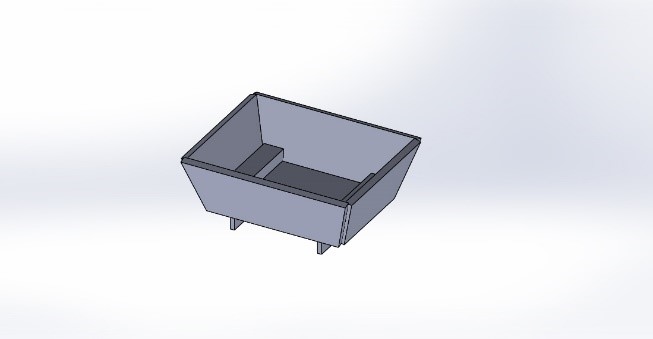

Ingot Casting Molds & Slag Skimming Pots: * Durability That Lasts.

-

Benefit: Heat-treated and reinforced to resist thermal fatigue. Our molds ensure uniform cooling and easy release, reducing scrap rates and improving the surface finish of your final product.

-

-

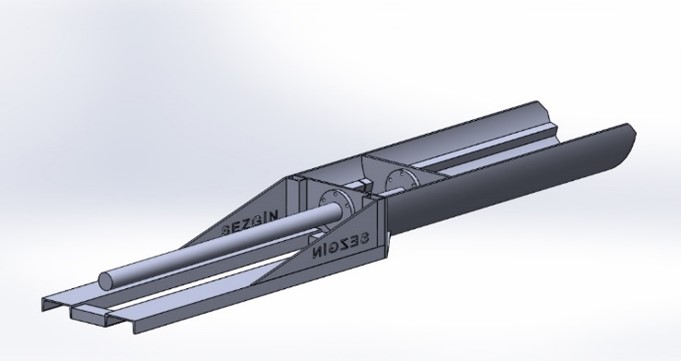

Compact High-Pressure Scrap & Ingot Press

Densify Your Profits. Optimize Your Melt.

The STM Compact Press is engineered to transform loose scrap and irregularly shaped metal into high-density bales. In modern smelting, density is everything. By compressing your material before it enters the furnace, you drastically reduce surface area—preventing oxidation (burn loss) and ensuring the metal sinks directly into the melt for maximum recovery.

-

Heavy-Duty Hydraulic Force: Massive compression power in a small footprint, designed for high-cycle industrial use.

-

Mobile & Versatile: Equipped with heavy-duty casters and forklift pockets for easy repositioning within your facility.

-

Simple Integration: Plug-and-play operation with an integrated hydraulic power pack and manual or semi-automatic control options.

-

3. Why Invest in STM Foundry Accessories?

-

🛡️ Protective Engineering: Every attachment is designed to be gentle on your furnace’s expensive refractory lining, extending its lifespan.

-

📉 Energy Recovery: By preserving heat during transfer (Yolluk) and charging, you drastically cut down on gas/electric consumption.

-

🧪 Superior Filtration: Well-insulated runners allow for “hot-pouring,” which means your ceramic filters perform at peak efficiency without clogging.

-

🦾 Worker Safety: Ergonomic designs reduce operator fatigue and keep personnel at a safe distance from extreme heat sources.