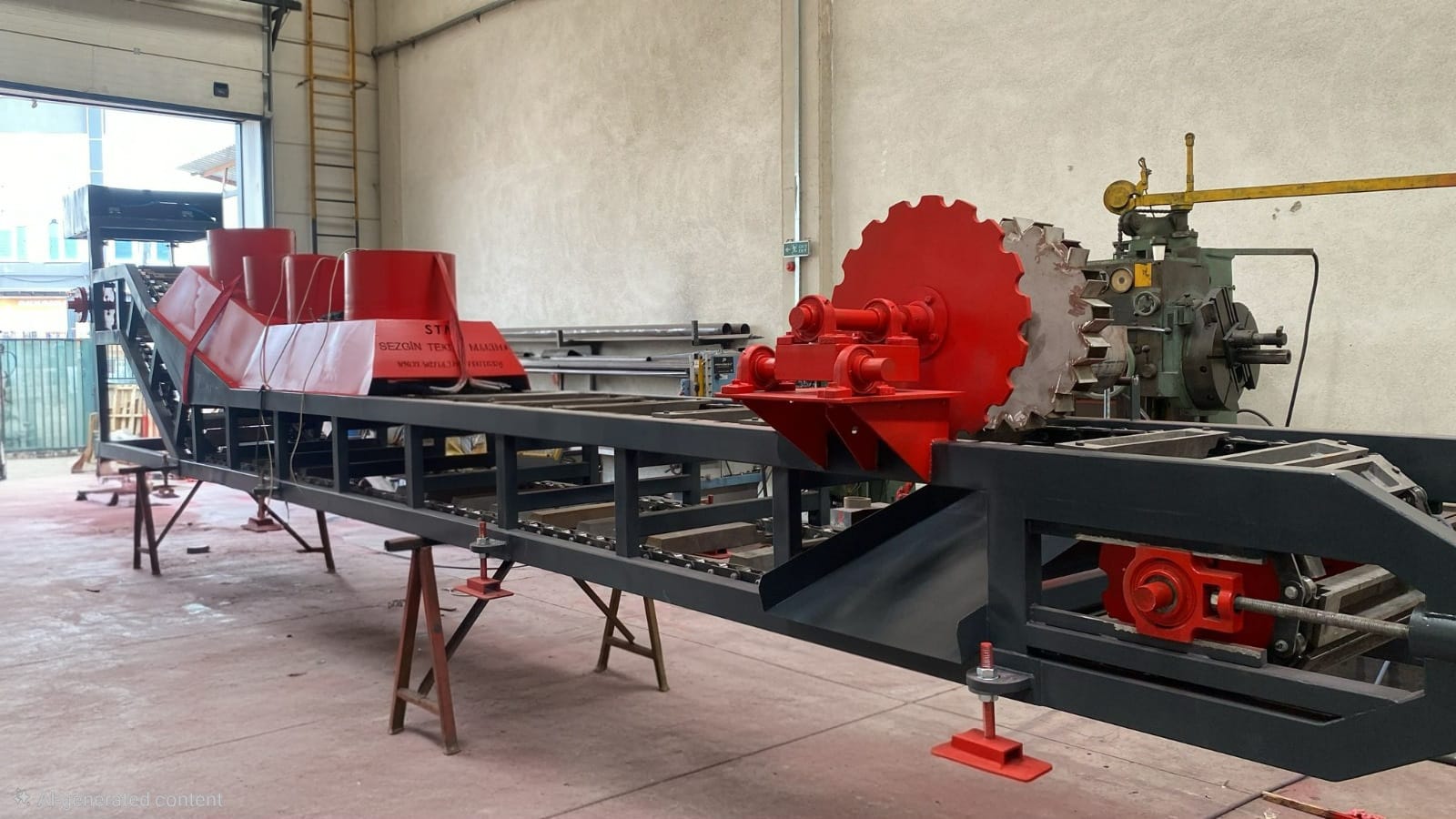

Heavy-Duty Ingot Casting Conveyor System (MS-SERIES)

Maximize your foundry’s productivity with our precision-engineered Ingot Casting Conveyor. Designed for continuous, high-temperature operation, this system automates the cooling and transport of aluminum, lead, or zinc ingots. Built for extreme industrial environments, it ensures uniform ingot quality while reducing manual labor and operational risks.

-

High-Temperature Resistance: Heavy-duty molds designed for thermal cycling.

-

Variable Speed Control: Precision PLC-integrated speed adjustment.

-

Automated Ejection: Smooth, damage-free ingot release mechanism.

Engineered for Extreme Performance

The STM Sezgin Teknik Ingot Casting Conveyor is the backbone of modern smelting operations. Every component is selected to withstand the rigors of molten metal environments, ensuring your production line never falters. From precision mold alignment to synchronized cooling intervals, this system delivers consistent results in every shift.

Key Technical Features & Advantages

-

Heavy-Duty Drive System: Equipped with a high-torque motor and reinforced chains for 24/7 reliability.

-

Customizable Mold Geometry: Molds can be tailored to your specific weight and dimensions requirements (Aluminum, Zinc, Lead, etc.).

-

Integrated Cooling Zone: Optional forced-air or water-mist cooling stations to accelerate cycle times.

-

Smart PLC Integration: Full synchronization with your existing melting furnaces via our intelligent control panel.

| Feature | Specification |

| Material Compatibility | Aluminum, Lead, Zinc, and Alloys |

| Control System | Siemens/Schneider PLC with Touch Interface |

| Cooling Method | Air-cooled / Water-mist (Optional) |

| Drive Power | Variable based on conveyor length |

| Safety Standards | CE Compliant with Emergency Interlocks |

| Frame Construction | Reinforced Structural Steel |

-

🚀 Boost Efficiency: Reduce manual handling by up to 80%, allowing your team to focus on quality control rather than heavy lifting.

-

🛡️ Enhanced Safety: Remove operators from the immediate vicinity of molten metal with fully automated pouring and transport.

-

📉 Lower Maintenance: High-grade bearings and self-lubricating chains significantly extend service intervals.